Quality Control

Excellence in Quality & Global Compliance

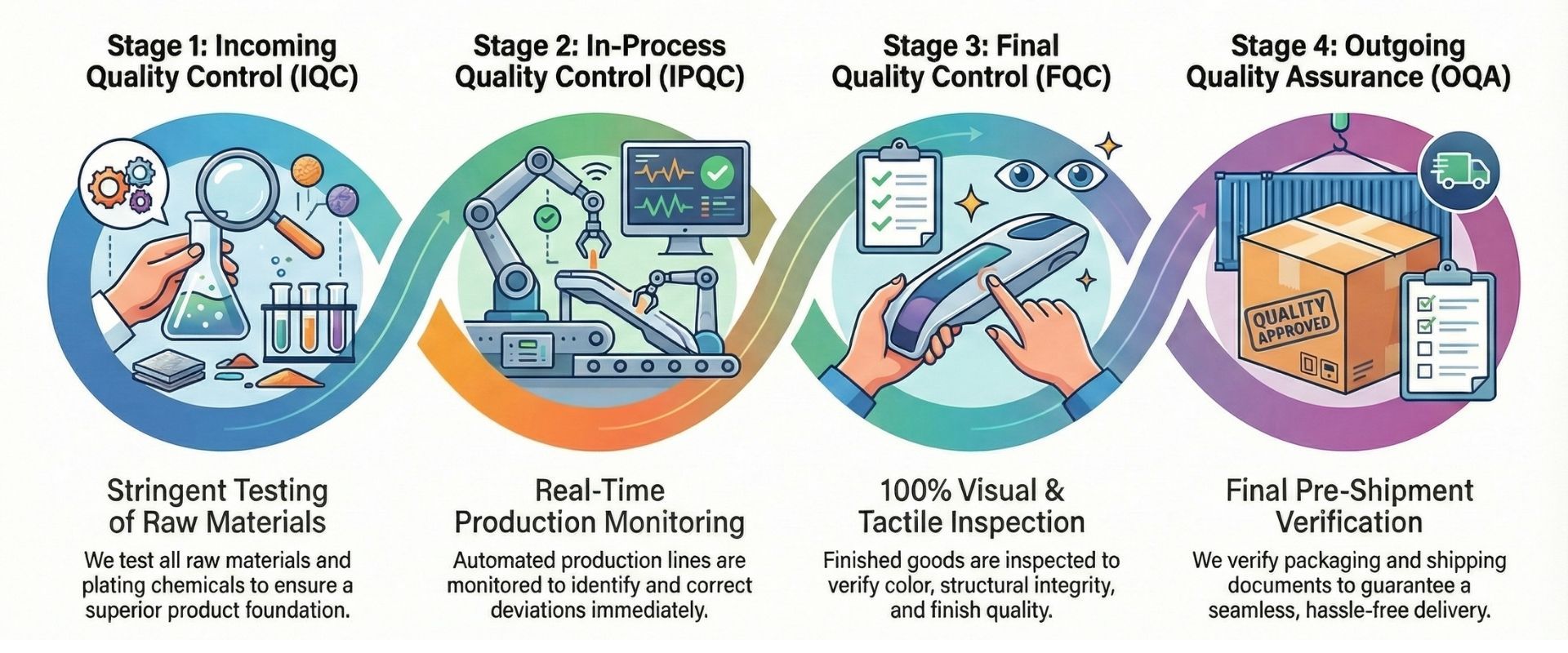

A comprehensive Source-to-Delivery philosophy ensures quality is built into every stage of production—not just inspected at the end. Our transparent QC system delivers the consistency, safety, and scalability demanded by leading global brands. By combining advanced technology with rigorous standards, we ensure every custom product accurately represents your brand identity.

Backed by decades of expertise and a proven compliance record, this commitment to precision has earned us the trust of the world’s most prestigious sporting events. As a long-standing manufacturer of Olympic lapel pins and medals, we consistently deliver products that meet elite global quality standards.

Why Global Brands Trust Our Quality Standards

Rigorous Multi-Stage Inspections From raw material sourcing to final packaging, we implement a multi-layered inspection strategy. Our Pre-Shipment Inspection protocols are designed to catch the slightest imperfections, ensuring a 0% defect goal before goods leave our facility.State-of-the-Art Technology We leverage advanced testing equipment and automated electroplating lines to ensure consistency. This precision allows us to maintain the highest tolerances and flawless finishes required by high-end international brands.Strict Compliance & Reliability Our processes are fully compliant with international safety and quality regulations. We provide our clients with the peace of mind that every product is not only aesthetically perfect but also ethically and technically sound.

Premium Material Sourcing & Validation

Quality begins at the source. We strictly manage our supply chain by partnering exclusively with certified suppliers who comply with international safety standards like RoHS and EN71. Through a rigorous Incoming Quality Control process, every batch of raw material—including metal, silicone, and fabric—undergoes thorough in-house or third-party laboratory testing for purity and durability. By verifying the integrity of every component before production, we ensure that every custom product is built on a safe and reliable foundation.

Advanced Manufacturing & In-Process Quality Control

We synergize advanced manufacturing technology with seasoned craftsmanship to ensure unwavering consistency for large-scale international orders. By leveraging high-precision molding, coloring, and finishing equipment, we guarantee that every detail reflects your exact specifications. This technical precision is reinforced by real-time in-process monitoring, where our dedicated QC team conducts continuous spot checks to promptly identify and correct deviations. Through this proactive approach, we ensure stable output quality and minimized defect rates across every production run.

Rigorous Pre-Shipment Inspection

Before shipment, all finished products undergo a comprehensive Final Quality Control process to verify appearance, structural integrity, and functionality. We ensure that every item and its packaging align perfectly with approved standards and international shipping requirements. By meticulously managing labeling and documentation, we guarantee global shipping readiness and smooth customs clearance, providing our partners with a seamless and reliable delivery experience worldwide.

Final Quality Verification & Global Compliance

At the final stage prior to shipment, our Outgoing Quality Assurance team conducts a rigorous, end-to-end inspection process. In addition to comprehensive functional and aesthetic evaluations, we perform specialized packaging integrity tests to ensure product protection throughout long-haul transportation. By strictly verifying batch consistency, labeling accuracy, and shipping documentation, potential logistics risks are effectively minimized while full compliance with regional import regulations is ensured. This final gatekeeping stage provides our global partners with a high level of confidence in product excellence and a seamless delivery experience.

Your Strategic Partner in Manufacturing

We are more than a supplier; we act as your dedicated QC task force in the East. By integrating deep technical expertise with a seamless one-stop service model, we bridge the gap between design and delivery while removing the inherent risks of international sourcing. Partner with us to experience the operational excellence, supply chain transparency, and unwavering reliability that have made us a trusted global leader for world-class brands.

Our Promise: Delivering Uncompromised Excellence

Our process ensures consistent results, full production transparency, and manufacturing reliability that strictly comply with global safety regulations. We don't just deliver products; we partner with you to provide the precision and trust necessary to elevate your brand’s reputation in the competitive global marketplace.