Colour Methods for Metal Lapel Pins

Emblem badge coloring

Cloisonné (Hard Enamel) Lapel Pins V.S. Imitation (Soft) Hard Enamel Lapel Pins

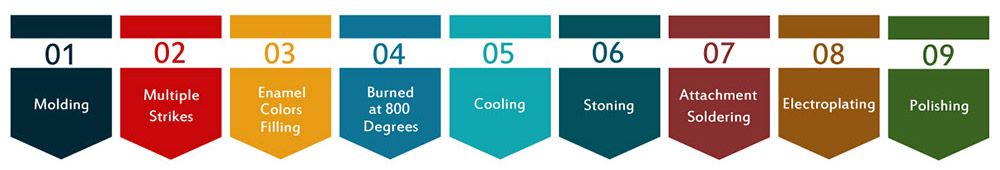

Cloisonné lapel pins is the highest quality product, and also called hard enamel pins, which normally created by a sheet of high quality copper.The painting process used in cloisonné enamel pins starts with enamel powder or mineral ore then burned at over 800°C degrees to harden and cure the enamel. Traditional Cloisonné lapel pins can be preserved for many years, it is a symbol of achievement and frequently used by different organizations. After polishing smooth, you can rub your finger over a cloisonné lapel pin you will feel smooth and you will not feel the metal borders / ridges. Nowadays, Imitation (Soft) Hard Enamel Lapel Pins are replaced to Cloisonné pins due to similar appearance, affordable price and color choices (PMS Pantone colors is available).

Soft Enamel Pins

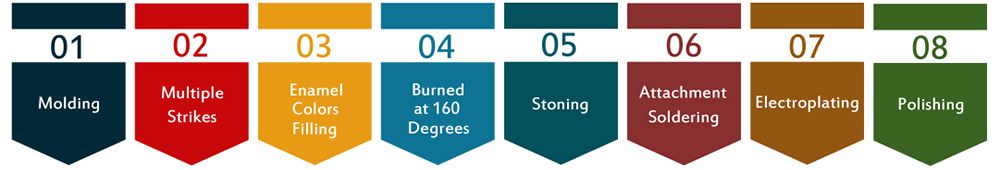

Soft enamel pins are the most popular pin types and offer great appearance at an affordable price, especially appropriate used for corporate pins and team trading pins. Colors are stored in syringes and applied by injection in the recessed areas and then bake the enamel hard. The enamel clings to the edges and recessed below the metal die line (that stops the enamels from mixing), meaning the paint is at a lower level than the metal borders surrounding. If you rub your finger over a soft enamel pin you will feel the raised metal lines. We also can add epoxy coating onto soft enamel to protect the enamel and make the enamel smooth and flat.

Two-Tone Die Struck Lapel Pins

One of the features of die struck pins is classic and produce only with a simple metal (without colors filling). Die struck lapel pins are made with a sheet of raw metal. Then, the mold is produced depending on your design and struck under extreme pressure. Multiple strikes are necessary required to ensure your design into the metal. Once the pin design is shaped onto the raw metal, the strip will be cut perfectly and separated into smaller strips. As the final procedure has been finished, it can be worked in many ways: plating, polishing or antiquing.

Printing Lapel Pins

99% of printing lapel pins normally with epoxy coating or lacquer coating on the surface to prevent ink to fall off.

Printing Lapel Pins

99% of printing lapel pins normally with epoxy coating or lacquer coating on the surface to prevent ink to fall off.

Printing Lapel Pins

99% of printing lapel pins normally with epoxy coating or lacquer coating on the surface to prevent ink to fall off.

- Video

- Test Report

-

Soft Enamel - EN71 (2017)

Soft Enamel Passes EN 71-3, ASTM F963-16-Standard Consumer Safety Specification on Toy Safety-Heavy Elements content, Japan Toy Safety Standard.

DownloadMixture Ink for Extra Printing - EN71 (2017)

Mixture Ink for Extra Printing Passes EN 71-3, ASTM F963-16-Standard Consumer Safety Specification on Toy Safety-Heavy Elements content and Japan Toy Safety...

DownloadMixture Ink for Offset or Pad Printing - EN71 (2017)

Mixture Ink for Offset or Pad Printing Passes EN 71-3, ASTM F963-16-Standard Consumer Safety Specification on Toy Safety-Heavy Elements content and Japan...

DownloadMixture Ink for Silkscreen Printing - EN71 (2017)

Mixture Ink for Silkscreen Printing Passes EN 71-3, ASTM F963-16-Standard Consumer Safety Specification on Toy Safety-Heavy Elements content and Japan...

DownloadMixture Ink for Extra Printing - CPSIA (2017)

Mixture Ink for Extra Printing Passes CPSIA section 101(f) (1)-Lead in paint / similar surface coating material and US California Proposition 65-Cadmium...

DownloadMixture Ink for Offset or Pad Printing - CPSIA (2017)

Mixture Ink for Offset or Pad Printing Passes CPSIA section 101(f) (1) - Lead in paint / similar surface coating material and US California Proposition...

DownloadMixture Ink for Silkscreen Printing - CPSIA (2017)

Mixture Ink for Silkscreen Printing Passes CPSIA section 101(f) (1) - Lead in paint / similar surface coating material and US California Proposition 65 - Cadmium...

DownloadSoft Enamel - CPSIA (2017)

Soft Enamel Passes CPSIA section 101(f) (1) - Lead in paint / similar surface coating material and US California Proposition 65 - Cadmium Content.

DownloadMixture of Soft Enamel - EN71 (2018)

Mixture of Soft Enamel Passes 19 Toxic Element Migration Test, Toxic Elements Analysis and Soluble Lead Content Test.

DownloadSoft Cloisonne - EN71 (2018)

Soft Cloisonne Passes 19 Toxic Element Migration Test, Toxic Elements Analysis and Soluble Lead Content Test.

DownloadMixture of Soft Enamel - CPSIA (2018)

Mixture of Soft Enamel Passes Total Lead (Pb) Content In Surface Coating and Total Cadmium (Cd) Content.

DownloadSoft Cloisonne - CPSIA (2018)

Soft Cloisonne Passes Total Lead (Pb) Content In Surface Coating and Total Cadmium (Cd) Content.

DownloadMixture Ink for Extra Printing - EN71 (2018)

Mixture Ink for Extra Printing Passes 19 Toxic Element Migration Test, Toxic Elements Analysis and Soluble Lead Content Test.

DownloadMixture Ink for Offset or Pad Printing - EN71 (2018)

Mixture Ink for Offset or Pad Printing Passes 19 Toxic Element Migration Test, Toxic Elements Analysis and Soluble Lead Content Test.

DownloadMixture Ink for Silkscreen Printing - EN71 (2018)

Mixture Ink for Silkscreen Printing Passes 19 Toxic Element Migration Test, Toxic Elements Analysis and Soluble Lead Content Test.

DownloadMixture Ink for Extra Printing - CPSIA (2018)

Mixture Ink for Extra Printing Passes Total Lead (Pb) Content In Surface Coating and Total Cadmium (Cd) Content.

DownloadMixture Ink for Offset or Pad Printing - CPSIA (2018)

Mixture Ink for Offset or Pad Printing Passes Total Lead (Pb) Content In Surface Coating and Total Cadmium (Cd) Content.

DownloadMixture Ink for Silkscreen Printing - CPSIA (2018)

Mixture Ink for Silkscreen Printing Passes Total Lead (Pb) Content In Surface Coating and Total Cadmium (Cd) Content.

Download - Related Products

-

Soft Enamel Pins

Depending on the design and purpose, soft enamel pin materials can be used for different types...

DetailsPrinted Lapel Pins

Discover a diverse selection of printed lapel pins, meticulously crafted from three premium...

DetailsPhoto Etched Pins

The production process of photo etched pin is drawing, making etching film, printing the image...

DetailsImitation Hard Enamel Pins

The biggest difference between imitation hard enamel pins and soft enamel pins effect is that...

DetailsCustom Hard Enamel Pin

Custom hard enamel pins are made from mineral ore imported from Japan. Personalized enamel...

DetailsRhinestone Lapel Pin

The rhinestone lapel pin process by die casting (zinc alloy) material and the attachment is brooch...

Details